Solar system

Installation and commissioning of a 130 kWp photovoltaic system on the roof of the production building.

Refrigeration system

Replacement of the existing refrigeration system with a modern, energy-efficient system that is operated with the environmentally friendly refrigerant R1234ze, which has a low global warming potential.

ecovadis silver 2021

Receipt of the "ecovadis in Silver" award for the assessment of corporate social responsibility and sustainable procurement.

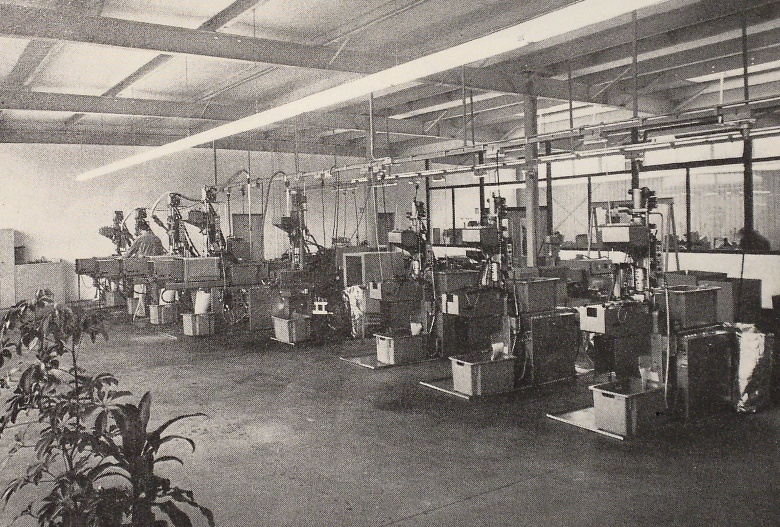

Assembly systems

Expansion of the pharmaceutical assembly area to include fully automated assembly systems.

Company handover to the next generation

Nicole and Michael Niesner continue their father's life's work and set the course for the successful future of Alfred Niesner GmbH.

Further increase in production capacity

- Strong growth in pharmaceutical products

- Increase in production capacity, investment in injection moulding machines up to 300 tonnes and hall expansion

- In Germany: Increasing specialisation in technical valve components, produced on all-electric injection moulding machines and injection moulds with up to 96 cavities (e.g. aerosol valve housings)

Restructuring and expansion

- 2012: Implementation of a pharmaceutical product line with three semi-automatic assembly machines and several injection moulds

- 2013: New placement of further injection moulds

- 2014: Expansion of the production area and construction of a logistics centre

Additional toolmaking location

- Establishment of a second location for toolmaking in Olomouc, near Brno

Further business expansion

- Realisation of an extensive customer project in 2003

- Development and production of the required pilot and series moulds

- Investment in second hall with high-bay warehouse

Foundation IDSC

- Foundation of the subsidiary IDSC in 1997

- Important capacity expansion - for more competitiveness with mixed price solutions

- Test phase for a manual assembly service

- Start with production hall in combination with small warehouse and administration building

The 90's

- Strong company growth, investments in new technologies

- The goals: Improvement of quality, service and reliability

- Certification according to DIN EN ISO 9001/9002 at the end of the 90s.

- Foundation of the subsidiary IDSC (1997)

Rebranding

- "Schreck & Niesner KG" and "Schneider GmbH" become "Alfred Niesner GmbH"

- Main activity becomes injection moulding for companies in the aerosol and pump spray industry

Relocation an expansion

- Relocation to Niedernhausen, takeover of Schneider GmbH

- Expansion of injection moulding capacities

Relocation

- Relocation to Frankfurt/M, expansion of the product range

- In addition to the manufacture of moulds, now also production of assembly machines

- First injection moulding department with 2 assembly machines at the end of the 70s